EV battery technology explained

Sure, the world of EVs might seem all new and slightly alarming to those who deeply understand how internal-combustion-engined cars work, but trust us, it’s not that hard. If you’ve ever had a mobile phone, or a laptop, you’ve dealt with batteries and recharging already. Just imagine your laptop with wheels and electric motors, and seats, and a boot and… well, you get the idea.

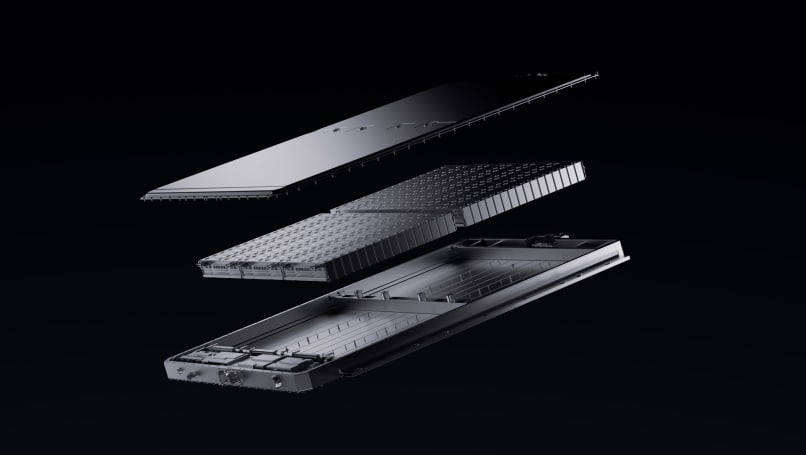

Battery Electric Vehicles (BEVs, or EVs), hybrids and Plug-in Hybrid Electric Vehicles (PHEVs) all use electricity that’s stored in a battery pack (so called because of the hundreds of individual battery cells packaged into modules or pockets) to power one or more electric motors.

There are several electric car battery types, however, and the batteries used in electric cars are a little more complicated than, say, the double-A batteries used to power up your TV remote control.

Typically the most common electric car battery is lithium-ion - Tesla car batteries are lithium-ion - and they are rechargeable, designed for a high kilowatt-hour (kWh) capacity and come with a comparatively good power-to-weight ratio, as well as specific energy and energy density.

Read more about electric car batteries

But there’s a war of price and technology going on behind the scenes, as the world’s biggest battery manufacturers, like BYD, CATL, LG Energy Solution, and Panasonic, race to offer the most driving range and performance by experimenting with new technologies and chemistries.

The good news being that consumers stand to win with more affordable electric and hybrid cars which can charge faster and drive longer distances.

Download the EVGuide Report, 2022

Australia's one-stop snapshot of all things relating to electric cars.

Check out our list below for an explainer of the types of batteries used in electric vehicles.

Lithium-Ion Batteries

Due to their high energy density and long cycle life, the lithium-ion car battery has become the leader in regards to electric car battery types.

Lithium-ion batteries are made primarily of carbon and highly reactive lithium, which can store a lot of energy. If you’re wondering what batteries most major manufacturers use in their EVs, it’s this one (both the Nissan Leaf battery type and Tesla Model 3 battery type are lithium-ion, for example).

But it’s not that simple. Lithium batteries can be broken down into two prevailing chemistries; the leading nickel manganese cobalt (NMC) and the increasingly popular lithium iron phosphate (LFP).

Nickel Manganese Cobalt (NMC)

NMC batteries have thus far been the most popular kind of electric car battery because they are more energy dense, lighter, and are able to put out serious power and accept serious charge.

Unfortunately, they are also expensive, accounting for much of an electric vehicle’s upfront cost, and they use rarer metals which are more expensive to acquire. On top of that cobalt has emerged as a controversial ‘risk’ material as it is often mined in locations where human rights are not a priority.

As such, many manufacturers are moving to trace how cobalt is sourced, and pick more ethical suppliers, as well as altering the chemistry slightly to reduce the amount of cobalt required.

Lithium Iron Phosphate (LFP)

LFP batteries are rapidly rising in popularity as they are more affordable and use less hard-to-source materials than NMC batteries. However, they come with downsides. For a start they are less energy dense, which means you need more batteries for the same kWh potential as an NMC battery, and they also tend to be more limited in how much power they can output to motors, or receive when charging.

As such, many lower-cost manufacturers like BYD rely on LFP batteries, while others like Tesla, Polestar, and Ford use LFP cells for their entry-level offerings.

LFP cells have also become somewhat controversial as they are less recyclable than their NMC counterparts. Technically, they can be recycled using similar methods (melting them down or chipping them up to separate the valuable materials out) but because the core metals in LFP batteries are so common, it is generally not economically viable to recycle them.

Nickel-Metal Hydride Battery (NiMH)

This older type of electric vehicle battery is typically used in hybrids - cars with both an electric motor and internal-combustion engine - such as the Toyota RAV4.

Nickel metal hydride batteries use hydrogen to store energy, with nickel and another metal (such as titanium) keeping a lid on the hydrogen ions.

NiMH batteries are significantly less expensive than lithium-ion batteries, but they are also larger and heavier, which can adversely affect the car’s performance.

They’re also able to hold around the same amount of energy as lithium-ion batteries, but the latter can be charged and discharged at a significantly more rapid rate.

While these traits make them less useful as a power source for a fully electric vehicle, they are much more viable for use in a plugless hybrid, although even now Toyota is phasing them out in favour of lithium-ion cells.

Research has shown that NiMH cells can be long-lasting and still operational after 160,000km and more than a decade of driving, but they do also suffer from poor efficiency, high self-discharge and poor performance when the weather turns cold.

Despite the rise of Lithium-ion, some of the biggest users of nickel-metal batteries continue to develop them. Toyota, for example, debuted a new NiMH battery in 2021 in its Aqua hatch using a ‘bipolar electrode’ which can expand its capacity by 1.4 times using the same space.

Lead-Acid Battery

EV battery types have historically come in several flavours, including your old-school lead-acid batteries, which are more commonly used as the 12-volt power source in combustion vehicles.

These common, simple, but heavy batteries powered some of the world’s earliest modern electric vehicles like the Nissan Tama (1947) up to the General Motors EV1 (1996).

Their popularity stems from being high-powered, inexpensive, safe and reliable, but there are some notable downsides too: weight, poor performance in cold weather, a short life span and low specific energy being the three big ones.

Storage capacity for lead-acid batteries decreases with lower temperatures, and diverted power to run a heating coil in an EV can reduce the efficiency and range by a whopping 40 per cent, making them not as viable as the high-voltage power source in a modern EV.

Sodium batteries

Sodium batteries have been pitched as a lower cost solution compared to the likes of the other batteries on this list, thanks to their use of more common materials. They can be split into two kinds which have been used for electric vehicles - the so-called molten salt battery (sodium-nickel-chloride or ZEBRA battery), and the more modern sodium-ion battery (SIBs).

Both have significant challenges associated with them, which have stopped them from being as commercially viable in the past, although as manufacturers search for even more affordable options, research has re-started on the technology.

Sodium-Nickel-Chloride Battery

Also known as a ZEBRA (Zeolite Battery Research Africa Project) battery, these are less commonly used in EVs, and were initially researched in the 1980s.

The ZEBRA is a rechargeable molten salt battery using common materials like nickel metal and the sodium and chloride from conventional table salt. It is said to be roughly four times as energy dense as a lead-acid battery.

They last for a few thousand charge cycles, but they have electrolytes that need to be heated to a toasty 270 degrees Celsius, which causes energy wastage and issues in relation to long-term charge storage.

Such a battery was used in the experimental Citroen Berlingo First Electric which was made in limited production originally with a nickel-cadmium battery, but later with a molten salt battery (2008).

Sodium-ion Battery (SIBs)

Working on a similar principle as a lithium-ion battery but replacing the lithium with common salt, the sodium-ion battery is theoretically much cheaper to build with less environmental impact, as it does not require large-scale mining of materials like lithium.

Sodium-ion batteries also have much lower energy density than lithium-based cells, and have a short cycle life, although they can charge much faster and are more resistant to low temperature operating conditions.

Chinese battery manufacturers are leading the charge on sodium-based batteries, which they see as having significant potential for smaller affordable vehicles, two-wheeled vehicles, electrified industrial equipment, or as a cheaper energy storage solution.

China’s CATL is selling a mass-scale sodium-ion battery and BYD is said to be working on one for its miniature Seagull hatchback. Prices are said to be 30 - 50 per cent lower than NMC cells, so it could bring the next big price-drop for electric vehicles since the widespread adoption of LFP.

What’s a new type of battery for electric cars?

As researchers and developers continue to refine electric car battery technology, a number of new variants of EV batteries are in the works.

The Lithium Vanadium Phosphate Battery (LVP) is a proposed type of lithium-ion battery that uses vanadium phosphate in the cathode, resulting in a safer and longer-lasting battery.

A lithium-air battery (Li-air) is one that can theoretically lead to electrochemical cells with the highest possible specific energy, but significant advancements in electrolyte development will be required before they are commercially available.

The lithium-sulphur battery (Li-S) is expected to one day supersede lithium-ion batteries due to its higher energy density, lower weight, and reduced cost, although problems leading to a low life-cycle of the battery have currently held up widespread implementation.

Aluminium-ion batteries (Al-ion) could also be a potential lithium-ion successor thanks to their low cost, low flammability, and even higher capacity. However, with current technology they have a shorter shelf-life and are much more vulnerable to temperature changes.

A solid-state battery is what the industry sees as the holy grail of battery technology. This type replaces the liquid gel found in current batteries with a solid electrode or solid electrolyte, like ceramics or solid polymers. They have far higher energy densities and are safer, but they are also currently very expensive.

They do potentially offer faster charging and a longer cycle life, however, so development on these as a potential replacement for lithium-ion batteries continues with multiple potential chemistries in the works from the world’s largest battery manufacturers.

How long do electric car batteries last?

We’ve answered the question “what are electric car batteries made of?”, but what about battery longevity?

This is a tricky one since how often you use your EV, how often you charge the vehicle and the power that you’re using to charge it with all impact the battery’s overall life. In short, there are a huge number of variables.

A reasonable prediction for battery life, however, is 10 to 20 years, which is a considerable improvement on the life expectancy of batteries in non-electric cars.

Most car manufacturers offer five to eight-year warranties on EV batteries, so placing the prediction at the more conservative end of the scale might offer a more realistic answer in relation to the battery’s expected life cycle.

If you’re concerned about waste after that 20-year mark, also consider that electric vehicle batteries can be repurposed and continue to be used in lower-voltage home storage solutions (some estimates expect for another 10 - 20 years), or the batteries can be melted down or chipped up to recover a large amount of the useful materials they contain. It is expected battery recycling will become a large industry in the next 20 years as electric vehicles and home battery storage becomes more common.

Comments